Which luxury card finishes suit premium brands best?

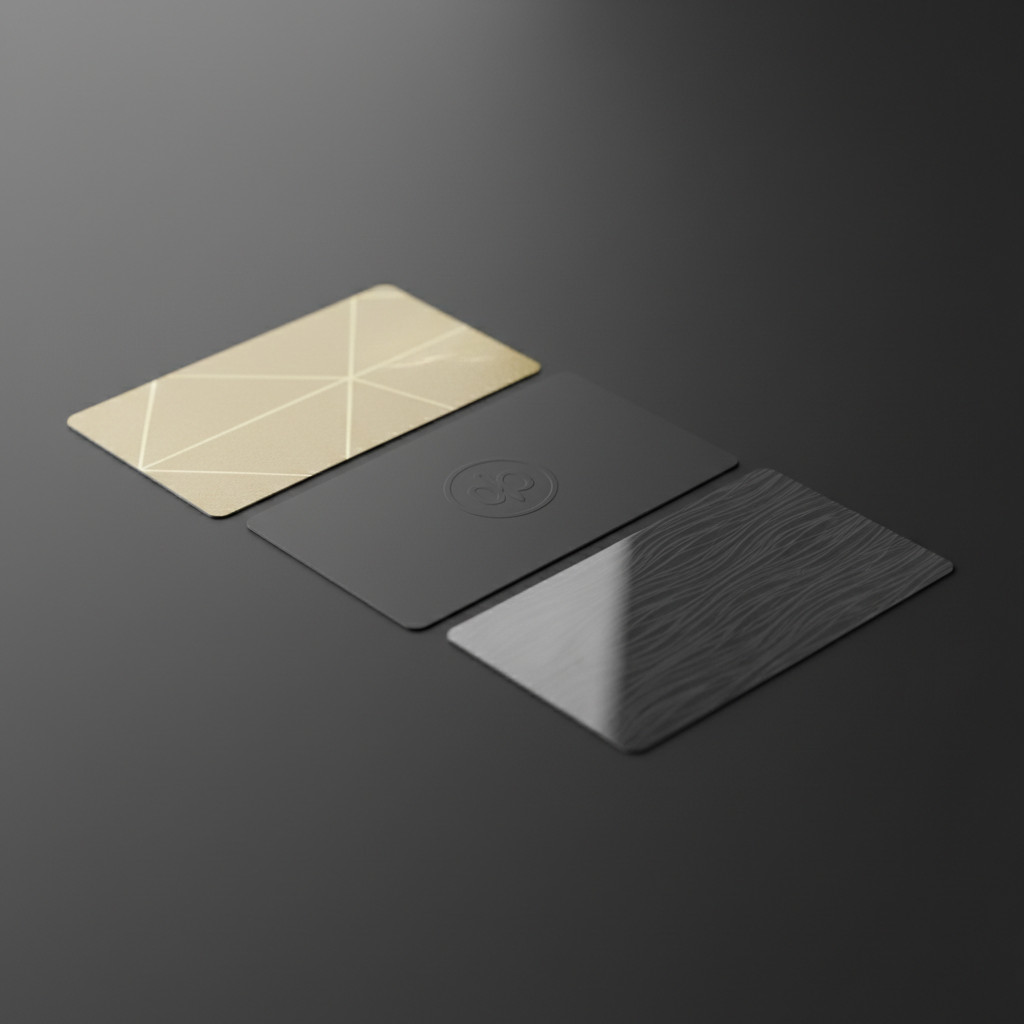

Luxury finishes: foil stamping, embossing and spot UV for premium membership cards

Luxury finishes transform ordinary membership cards into memorable brand assets. Because first impressions matter, tactile and visual details shape member perception instantly. Foil stamping, embossing and spot UV add shine, depth and contrast to designs. As a result, brands command attention and justify premium tiers or experiences.

This comprehensive guide explains practical uses, design tips and production tradeoffs. However, not every finish suits every brand or budget, so we compare options. You will learn when to use metallic foil, raised embossing or selective spot UV. We will also cover substrate choices, artwork preparation and finishing limitations. Finally, the guide highlights real world examples and cost versus impact considerations.

We include practical artwork preparation tips to avoid print surprises. Moreover, we discuss sustainability and finishing choices that lower environmental impact. Because quality matters, you will get supplier and production checklists to follow. Start here to create membership cards that elevate your brand and delight members.

Luxury finishes and plastic card materials

Plastic membership cards start with the substrate. PVC remains the industry standard because it is flexible, printable and cost effective. However, PET and PETG offer higher clarity and heat resistance, so they suit foil stamping and lamination better. Recycled PVC provides an eco friendly option, and wood veneer or metal core cards deliver a premium feel. Because thickness affects embossing and chip embedding, choose 0.76 mm for standard cards or 1.0 mm for durability.

Luxury finishes with NFC and RFID card technology

Contactless functions rely on embedded antennas and chips. NFC chips follow standards set by the NFC Forum, and common RFID families include MIFARE Classic, MIFARE DESFire and EM4100 for low frequency. Therefore, choose DESFire for secure access control because it supports encryption and multiple applications. For payments or identity, dual interface or contact chips meet ISO7816 standards. However, finishing can interfere with antenna performance, so avoid full metal foils over the antenna area.

Luxury finishes and chip options, durability and production notes

Chip type determines use cases. Memory only chips are fine for simple loyalty IDs, but secure CPU chips enable payments and encrypted access. Additionally, chip placement requires a clear window during laminating. Embossing adds tactile depth, and spot UV highlights printed elements without altering card thickness. Foil stamping gives metallic shine, but it adds heat during production; as a result, suppliers may limit foil on cards with sensitive electronics. For best results, consult your printer early, test prototypes, and choose materials that balance aesthetics, durability and function.

Pros and cons

- PVC: low cost, widely supported

- PET/PETG: heat resistant, more durable

- Recycled: sustainable, variable quality

- Metal core: premium, may require antenna redesign

Choose materials and chips that match your budget, security needs and desired luxury finish.

| Card type | Typical industry use | Material | Chip options | Common benefits |

|---|---|---|---|---|

| Membership cards | Clubs, premium programs, elite loyalty | PVC, PET, PETG, metal core | NFC, MIFARE DESFire, contact chips | Premium feel, collectibility, multi function use Which luxury card finishes best suit premium brands? |

| Loyalty cards | Retail, cafes, subscription services | PVC, recycled PVC | Simple memory chips, NFC for tap to collect | Boost repeat sales, easy integration, low cost |

| Hotel key cards | Hotels, resorts, short stay access | PVC, PET with magnetic stripe or RFID inlay | EM4100, MIFARE Classic, MIFARE DESFire | Guest convenience, branding opportunity, controllable access How do custom-printed keycards boost hotel guest experience? |

| EV charging cards | Mobility networks, charging operators | PVC, PET with lamination | NFC, MIFARE DESFire, contactless secure chips | Fast authentication, account linking, durable |

| Access control cards | Offices, secure sites, events | PVC, PET, proximity cards, metal variants | MIFARE DESFire, HID iCLASS, smart CPU chips | Strong security, audit trails, multi application support Can RFID security prevent cloning and fraud? |

Customization options for luxury finishes

Brands can tailor cards to fit identity and function. Choose materials like PVC, PETG, metal core or wood veneer. For finishes, select foil stamping, embossing, spot UV or soft touch lamination. For personalization, use variable data printing, photo IDs, sequential numbering and magnetic stripes or NFC encoding. Additionally, choose edge printing, rounded corners and specialty cuts. Because electronics matter, reserve antenna areas from metallic finishes. Finally, prototypes confirm look and function before mass runs.

Common personalization options

- Variable data printing for names, barcodes and QR codes

- Hot foil stamping in gold, silver or holographic foils

- Blind embossing or raised embossing for logos and numbers

- Spot UV to highlight logos and key graphics

- Full colour digital or offset printing with white ink on dark substrates

- NFC/RFID encoding, magnetic stripe encoding or contact chip programming

- Laminates: gloss, matte, soft touch, or tamper-evident overlays

Printing processes and quality control for luxury finishes

Begin with artwork check and colour proofing. Then choose digital or offset print based on volume. Next, apply encoding and lamination, then finishing. Finally, run inspection and functional testing.

Typical production steps

- Prepress: file check, colour separation and proof approval

- Printing: digital, offset or dye sublimation

- Encoding: magnetic, RFID or NFC programming and testing

- Finishing: foil stamping, embossing, spot UV, cutting and corner rounding

- Final QC: adhesion tests, read/write checks and visual inspection

For reliability, test samples under use conditions. Also, work with your supplier early to avoid production surprises. As a result, you secure consistent quality and a premium member experience.

Conclusion

To summarize, foil stamping, embossing and spot UV lift membership cards visually and tactilely. These finishes create perceived value, highlight brand identity and improve member engagement. Choosing the right substrate, chip and finish requires balancing aesthetics, function and budget. We covered material choices, NFC and RFID chip options, and production steps. Therefore, testing prototypes and coordinating with your supplier avoids expensive surprises.

Flex Card Print is a UK based card printing specialist. They specialise in high quality plastic cards and secure NFC and RFID solutions. Because they handle material selection, encoding and finishing, clients get reliable end to end service. They also provide prototyping, quality control and logistics support. They support sustainable options and compliance testing.

If you want cards that combine luxury finishes with secure functionality, consider Flex Card Print. Visit Flex Card Print or email sales@flexcardprint.co.uk to discuss your project. Their team will advise on finishes, chips and production timelines. As a result, you reduce risk and launch premium cards faster.

Frequently Asked Questions (FAQs)

What materials work best for luxury membership cards?

Most projects use PVC for affordability and PET or PETG for extra durability. For premium tactile appeal, brands choose metal core or wood veneer. Additionally, recycled PVC offers a greener option. Because each material behaves differently with finishes, test samples first.

How do NFC and RFID technologies differ, and which should I choose?

NFC uses short range communication and works with smartphones. RFID covers a broader range and includes low frequency proximity chips. Therefore choose NFC for mobile interactions and RFID DESFire for higher security access control. For payments, use secure CPU or dual interface chips.

Can foil stamping embossing or spot UV affect card electronics?

Yes, metallic foils or thick metal layers can interfere with antennas. As a result, avoid placing full metal finishes over antenna zones. However, spot UV and blind embossing rarely affect read performance. Always consult your supplier and run read write tests on prototypes.

What customization options can I add, and how long does production take?

You can add variable data, hot foil, raised embossing, edge printing and NFC encoding. Typical lead times vary with complexity. For simple digital prints expect one to two weeks. However, bespoke foils, embedding chips and testing can extend production to three to four weeks. Also factor in shipping and approval time.

How do I choose the right card type for my project?

Start by listing the card functions and the desired user experience. Then weigh security needs, budget and finish level. For example, choose DESFire for secure access and metal core for premium membership cards. Finally, request prototypes and consult a specialist to confirm the final specification.

If you need help specifying materials, finishes or chips, contact Flex Card Print or visit our website.