What are the benefits of embossing in luxury finishes?

Luxury finishing techniques: when to use foil, embossing and soft-touch lamination

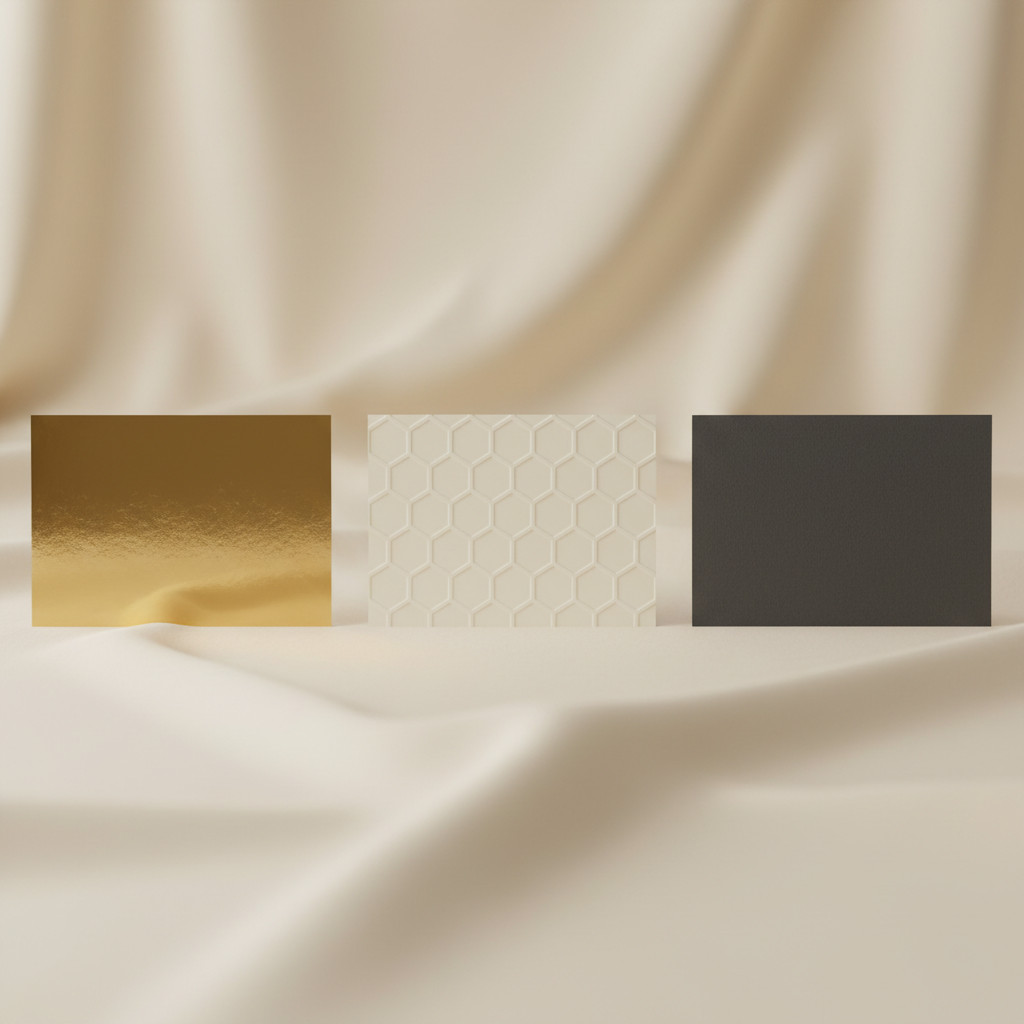

Luxury finishing techniques can turn ordinary print into tactile, memorable brand moments. Foil stamping, embossing and soft-touch lamination add perceived value quickly, and they guide customer impressions. Because touch influences trust, these finishes often lift response rates and elevate packaging, invitations and premium cards.

In this guide we explain when each finish works best and why. First, we define foil stamping, embossing, and soft-touch lamination. Then, we compare cost, durability and tactile effect. As a result, designers and marketers can choose the right finish for brand goals.

Along the way we highlight related keywords for SEO. Examples include premium finishes, tactile finishes, foil stamping techniques, debossing alternatives and soft touch coating. Therefore, you will learn practical rules of thumb and production tips. However, we keep explanations simple and visual, so you can act fast. Ultimately, this introduction helps you pick finishes that match budget and audience.

Luxury finishing techniques: when to choose foil or embossing

Foil and embossing create noble, tactile focal points. Foil adds shine and contrast, while embossing adds depth and feel. Because foil reflects light, it works best for logos and small accents. However, embossing suits larger areas and subtle luxury.

Quick rules of thumb

- Use foil when you want visual pop and high perceived value. For examples and case studies, see this link.

- Choose embossing for tactile logos or patterns that invite touch. It pairs well with soft-touch lamination.

- Combine foil and embossing sparingly to avoid a cluttered look.

“Touch influences trust, and well chosen finishes lift perceived value.” — Flex Card Print, see this link.

Luxury finishing techniques: cost, durability and production tips

Costs vary by complexity and quantity, so plan early. Soft-touch lamination adds a velvety surface, and therefore it increases durability and perceived quality. As a result, brands often use soft-touch on premium cards and packaging.

Production tips

- Allow extra lead time for specialised dies and foil plates. First proofs catch alignment issues.

- Check print-ready files before submission to avoid delays. Learn practical file checks at this link.

- Consider eco options where possible. For guidance on greener substrates, visit this link.

Key facts

- Tactile finishes influence purchase intent and brand recall. Therefore, designers should match finish to audience and use case.

- Use simple type and strong contrast when applying foil, and avoid fine hairlines that can fail in production.

These insights help you pick finishes that fit budget, timeline and brand goals.

Quick comparison: Luxury finishing techniques

| Feature | Luxury finishing – Foil (foil stamping) | Luxury finishing – Embossing (raised or deboss) | Luxury finishing – Soft-touch lamination (velvet feel) |

|---|---|---|---|

| Visual effect | High shine and metallic contrast | Subtle depth and shadow play | Matte, muted luxury with soft glow |

| Tactile feel | Smooth, slightly raised foil edges | Noticeable raised or recessed texture | Velvety, soft surface that invites touch |

| Best uses | Logos, small accents, invitations | Seals, monograms, larger brand marks | Premium cards, covers, packaging panels |

| Cost | Moderate to high for custom foils | Moderate for custom dies and setup | Moderate; adds lamination cost per unit |

| Durability | Good, but foil can scratch over time | Very durable when produced correctly | Excellent resistance to scuffs and fingerprints |

| Lead time | Longer for foil plates and proofs | Longer for die creation and testing | Shorter; standard lamination workflows apply |

| Production tips | Use bold type and strong contrast | Test depth to avoid registration issues | Combine with embossing sparingly for impact |

| Eco considerations | Foil adds metallic waste | Dies are reusable, so less waste over runs | Choose recyclable lamination where possible |

This table summarises key benefits, limitations and practical tips. As a result, designers can match finish to brand goals and budget.

Evidence: Luxury finishing techniques lift perceived value

Research and industry reports show that tactile finishes affect buyer perception. For example, tactile packaging improves memory recall and perceived price. Therefore, finishes like foil, embossing and soft-touch lamination matter for brand experience. As a result, marketing teams often prioritise finishes in premium campaigns.

Key evidence and facts

- Tactile finishes increase attention and encourage touch, which boosts trust and recall. Consequently, brands using tactile finishes report stronger brand impressions.

- Foil highlights small design elements effectively. However, it can scratch if not produced correctly. Therefore, test proofs carefully.

- Soft-touch lamination reduces fingerprints and adds a velvet feel. Thus, it extends perceived longevity for premium cards and boxes.

Examples: Real-world uses of luxury finishing techniques

Below are practical examples that show how finishes work in context. Each example pairs marketing goals with a finish.

- High-end invitations: Use foil for logos and embossing for seals. This combination signals exclusivity and ceremony.

- Premium membership cards: Apply soft-touch lamination to invite handling. Then add a small foil logo for prestige.

- Cosmetics packaging: Use soft-touch panels with subtle embossing. As a result, shoppers perceive higher quality at shelf.

“Well chosen finishes lift perceived value and extend the brand story.” — industry creative lead

Takeaway

Match finish to the audience and use case. Also, always order proofs and check print-ready files before full runs. That reduces costly reprints and ensures the tactile finish performs as intended.

Conclusion

Choosing the right luxury finishing technique—foil stamping, embossing or soft-touch lamination—changes how customers perceive your brand. Foil adds metallic accent and visual pop, whereas embossing adds depth and tactility. Soft-touch lamination lends a velvety matte feel and improves durability. Therefore, match finish to audience, budget and use case. As a result, you will boost perceived value and recall.

Flex Card Print is a UK-based card printing specialist with deep expertise in premium finishes and card production. They offer foil stamping, embossing, soft-touch lamination, NFC encoding and quality proofs. Moreover, their team guides file preparation, production timelines and eco-conscious material choices. Consequently, brands trust them for consistent results and dependable service.

Ready to upgrade your cards or packaging? Contact Flex Card Print for samples, a quote or a free consultation. Visit Flex Card Print or email sales@flexcardprint.co.uk. They will review your design and recommend the best finish for impact and budget. Get started today.

Website: Flex Card Print

Email: sales@flexcardprint.co.uk

Frequently Asked Questions

What is the difference between foil, embossing and soft-touch lamination?

Foil stamping adds metallic shine and high contrast. Because foil reflects light, it highlights small details like logos.

Embossing raises or recesses the printed surface. Therefore it creates depth and a tactile pattern that invites touch.

Soft-touch lamination gives a velvety matte finish. As a result, it feels premium and resists fingerprints.

Which finish should I choose for membership cards or premium credentials?

Choose soft-touch when you want repeated handling and a luxury feel. Moreover, it pairs well with durable cores.

Add a small foil logo for prestige, but keep foil elements bold and simple. However, avoid fine hairline foil that can fail in production.

Consider embossing for monograms or seals that need tactile emphasis.

How do finishes affect cost and lead time?

Foil and embossing need setup, such as dies and plates. Therefore they add upfront costs and increase lead time.

Soft-touch lamination has lower setup but adds a per-unit lamination cost. As a result, per-unit costs fall at higher volumes.

Plan production early and order proofs. That reduces misprints and unexpected reprints.

Are these finishes durable for everyday use?

Embossing is highly durable when done correctly. It survives frequent handling.

Foil looks luxurious, but can scratch over time. Protect foil zones by restricting abrasion.

Soft-touch resists fingerprints, yet it may scuff with heavy abrasion. Therefore use robust card cores and consider edge sealing.

Can luxury finishes be eco-friendly?

Yes. Choose recyclable lamination and FSC certified board. Moreover, ask printers about recyclable or water-based foils.

Request material datasheets and recycling guidance from your supplier. As a result, you can balance luxury and sustainability.

If you need help choosing finishes for purpose, durability or budget, request samples and proofs from your chosen supplier.