How Do Luxury Finishes Transform Cards and Packaging?

Luxury finishes explained: foil, embossing, soft-touch and when to use them

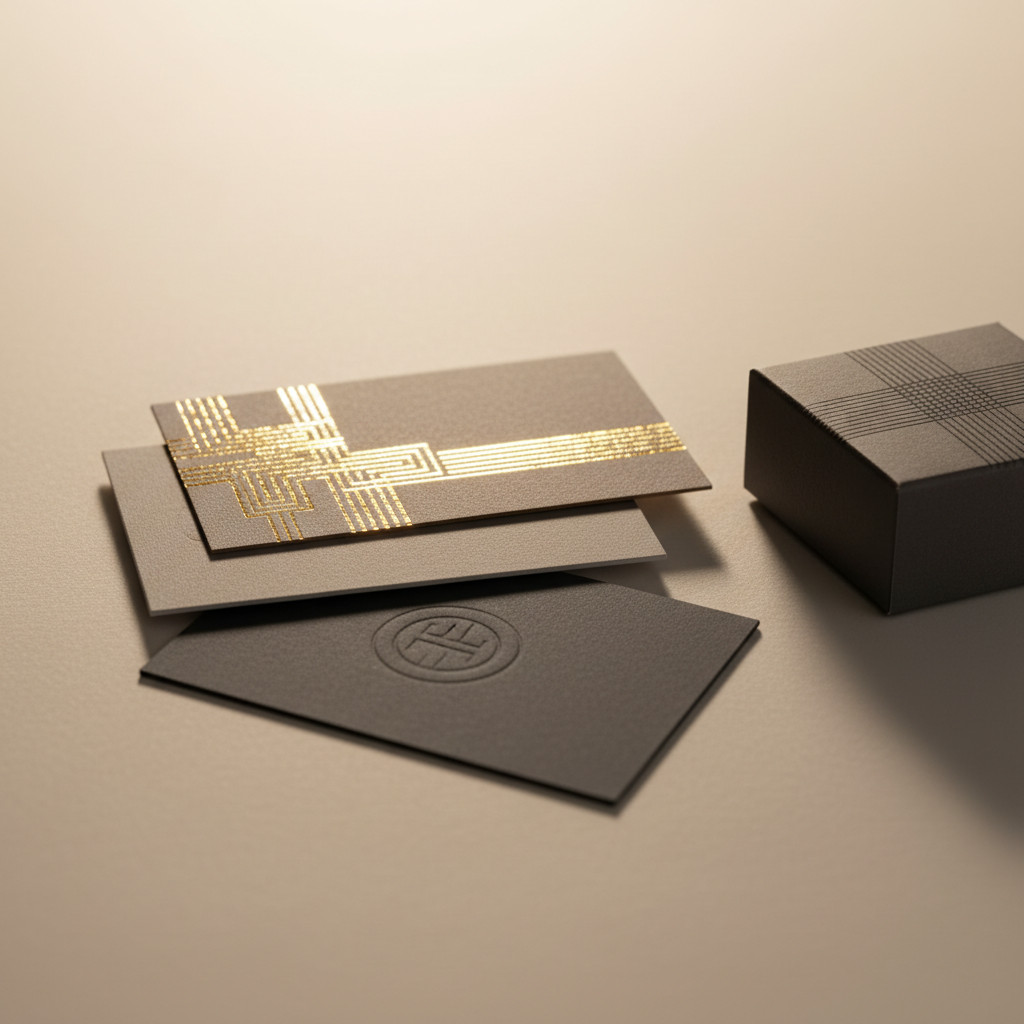

Luxury finishes can turn a good design into an unforgettable experience. Because first impressions matter, designers now choose tactile and visual effects to signal quality. This guide explains luxury finishes such as foil stamping, embossing, and soft-touch coating. It also covers when to use spot UV and tactile varnishes for maximum impact.

Flex Card Print has produced premium cards and packaging for hospitality and retail clients. Their work illustrates these principles. High-end printing increases perceived value quickly. However, it also requires careful material and finish choices.

Therefore this article breaks down each technique, compares costs, and gives real-world use cases. You will learn when to pick foil for shine, embossing for texture, and soft-touch for a velvety feel. By the end, you will know how to build cohesive brand touchpoints across cards, signage, and packaging.

Alongside technique breakdowns, we explore building brand cohesion across cards, signage and packaging. We include customer case studies that showcase standout visual campaigns and high-end printing applications. Read on to match finish, budget, and audience for memorable results.

Luxury finishes breakdown: foil, embossing, soft-touch explained

Luxury finishes help brands stand out quickly, because they add both visual and tactile cues. Foil stamping creates a metallic shine and works well on dark substrates. Historically, foil stamping has roots in 19th century bookbinding and evolved into modern hot foil techniques. Embossing raises parts of the paper or card, creating a tactile ridge that invites touch. Soft-touch coating adds a velvet, matte feel that reduces glare and communicates refinement.

Key characteristics

- Foil stamping: metallic shine, high contrast, best for logos and focal elements. However it can cost more at small runs.

- Embossing: tactile depth, durable impression, pairs well with foil for double impact. Therefore it suits premium invitations and packaging.

- Soft-touch coating: velvet finish, scratch resistance, ideal for cards and signage handled often.

Practical notes

- Substrate matters. For example, thicker card stocks take embossing better.

- Color choices affect result because metallic foils reflect differently under light.

- Flex Card Print recommends proofs before full runs to check alignment and registration.

Because each technique changes production steps, plan timelines accordingly. Embossing and foil require additional dies and setup time. As a result lead times extend slightly compared with standard digital print.

When to use luxury finishes for brand cohesion across cards, signage and packaging

Luxury finishes support cohesive branding when used consistently. For example, match foil on business cards with metallic accents on packaging. However avoid applying every finish at once, because overuse dilutes impact. Start with a primary finish and add accents as needed.

Decision checklist

- Audience and touchpoints: use soft-touch for high-contact items, because people feel it first.

- Hierarchy: reserve foil for primary logos and embossing for secondary elements.

- Budget: budget for die creation and finishing steps, as costs scale with complexity.

Case guidance

- For hospitality and retail, combine soft-touch exteriors with foil logos inside. Flex Card Print often produces paired samples to test this mix. Therefore sampling saves money and prevents surprises.

Use consistent materials, color palettes, and finish choices across touchpoints to strengthen recognition and perceived value.

| Finish | Best uses | Key benefits | Cost and lead time |

|---|---|---|---|

| Foil stamping | Logos, business cards, luxury packaging | High shine and contrast. Because foil reflects light, it draws the eye and signals premium quality. Works well on dark stocks. | Moderate to high cost for small runs. Setup requires foil dies; lead time increases by several days. |

| Embossing / Debossing | Invitations, seals, cover panels | Adds tactile depth and perceived value. Therefore it invites touch and lingers in memory. Pairs well with foil for emphasis. | Moderate cost. Requires dies and proofing. Lead time extends due to finishing steps. |

| Soft touch coating | Business cards, brochures, high contact items | Velvet matte feel that reduces glare and resists scratches. As a result it improves handling and perceived quality. | Low to moderate cost. Applied in an extra coating pass; slight lead time increase. |

| Spot UV and tactile varnish | Focal patterns, accents, photo highlights | Creates glossy contrast and selective texture. However overuse can overwhelm design. Use sparingly for impact. | Low cost per unit, but requires precise registration. Adds minimal lead time. |

Evidence and payoff: real examples and practical guidance

High-end finishes deliver measurable brand effects when applied with intent. For example, embossing and foil often increase perceived value at point of contact. Because tactile cues influence buying decisions, they work well in hospitality and luxury retail. Flex Card Print recommends sampling finishes before full production to control costs and ensure accuracy. See guidance on preparing files at here for reliable proofs.

Practical case studies

Hospitality welcome packs: A boutique hotel used soft-touch covers with foil logos for VIP room keys and packaging. As a result guests reported a more premium arrival experience. Therefore using consistent finishes across cards and packaging amplified brand memory.

Retail limited editions: A fashion label combined spot UV on imagery with blind embossing for a seasonal box. The limited run sold out faster than expected because the finish raised perceived rarity.

Sustainable premium cards: Brands moving to alternative substrates saw strong positive reactions. For sustainable options and substrate advice, review here and here.

Production evidence and tips

Start with prototypes. Because embossing and foil need dies, prototypes save money.

Control artwork: register marks and vector files help align foil and embossing. Therefore follow print-ready rules closely.

Match finishes to touch frequency: use soft-touch for items handled often, because it resists fingerprints and improves comfort.

Technical references

For historical context and process details see foil stamping at here.

For embossing process specifics see here.

Cost versus payoff

Expect higher setup costs for foil and embossing. However the per-unit price falls with larger runs.

Spot UV and soft-touch often add less cost. As a result they offer a good balance for mid-range budgets.

Combine selectively: reserve high-cost finishes for brand-critical touchpoints to maximise ROI.

Quick checklist before ordering

Choose substrate and weight that suit embossing.

Request physical proofs if possible. Flex Card Print advises testing finishes in real light.

Budget for dies and extra run time. Therefore add buffer days to launch schedules.

These steps ensure finishes support your brand promise. Moreover they turn ordinary print into memorable brand moments.

Conclusion: Luxury finishes and cohesive brand touchpoints

Luxury finishes create memorable brand moments and elevate perceived value quickly. Because foil, embossing, and soft-touch each offer distinct visual and tactile cues, they suit different uses. Foil adds shine and focus. Embossing invites touch and depth. Soft-touch gives a velvet, high-contact feel.

Apply finishes with hierarchy and restraint. Start by choosing one primary finish and use accents where they help. For example, reserve foil for logos and use embossing for secondary elements. Also test samples and proofs before full runs. Flex Card Print recommends prototypes to avoid misalignment and wasted budget.

Choose materials and finishes that match touchpoints across cards, signage, and packaging. As a result your brand will feel cohesive across customer journeys. For hospitality and retail, these choices can improve perceived quality and guest experience.

Flex Card Print is a UK-based card printing specialist. They offer quality plastic cards, NFC and RFID cards, and full-service design and finishing. For enquiries visit Flex Card Print or email sales@flexcardprint.co.uk. Contact them to discuss finishes, samples, and production timelines.

Frequently Asked Questions (FAQs)

What are luxury finishes and why use them?

Luxury finishes are treatments like foil, embossing, and soft-touch. They add visual and tactile cues that elevate perceived value. Because customers notice touch and shine first, finishes work well for premium packaging and cards.

Which finish suits business cards, packaging, and signage?

Use soft-touch for high-contact cards. Use foil for logos and focal points. Use embossing for seals and tactile elements. However combine finishes sparingly to avoid visual clutter.

Do finishes add much cost and lead time?

Yes, some do. Foil and embossing require dies and extra setup, so costs rise for small runs. As a result, plan extra lead time. Spot UV and soft-touch add less cost and scale better.

How should I prepare artwork for foil and embossing?

Supply vector logos and separate layers for each finish. Also include clear registration marks and request a physical proof. Flex Card Print recommends prototypes to check alignment and material choice.

Can I use sustainable materials with luxury finishes?

Yes, sustainable substrates like thick recycled board and wood veneers work with many finishes. Therefore test samples first, because some coatings behave differently on alternative stocks.